EYEVAN × KYOTO

interview 11

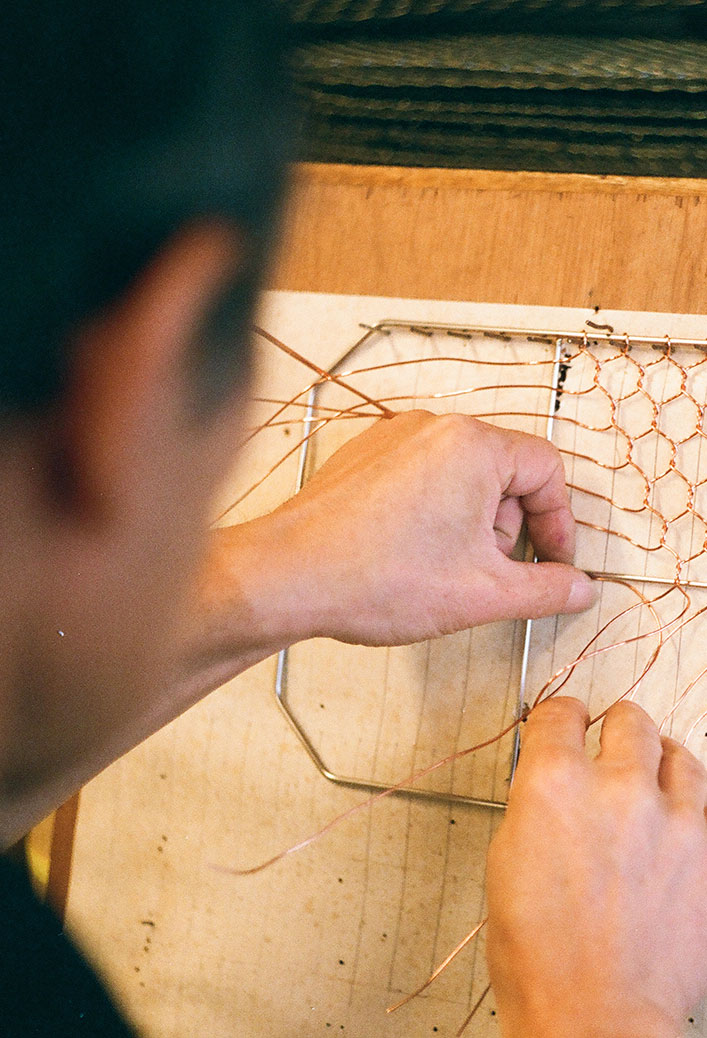

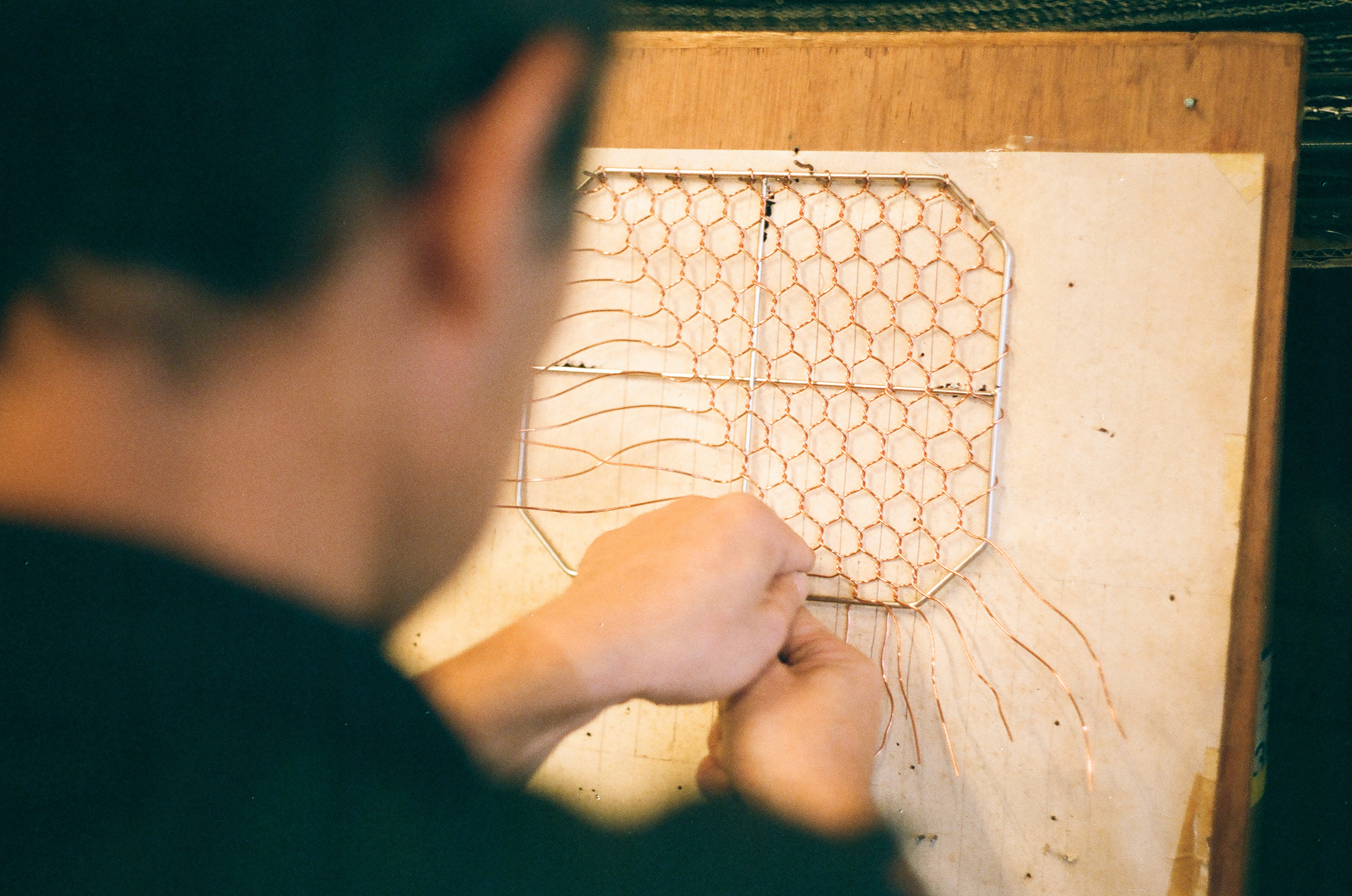

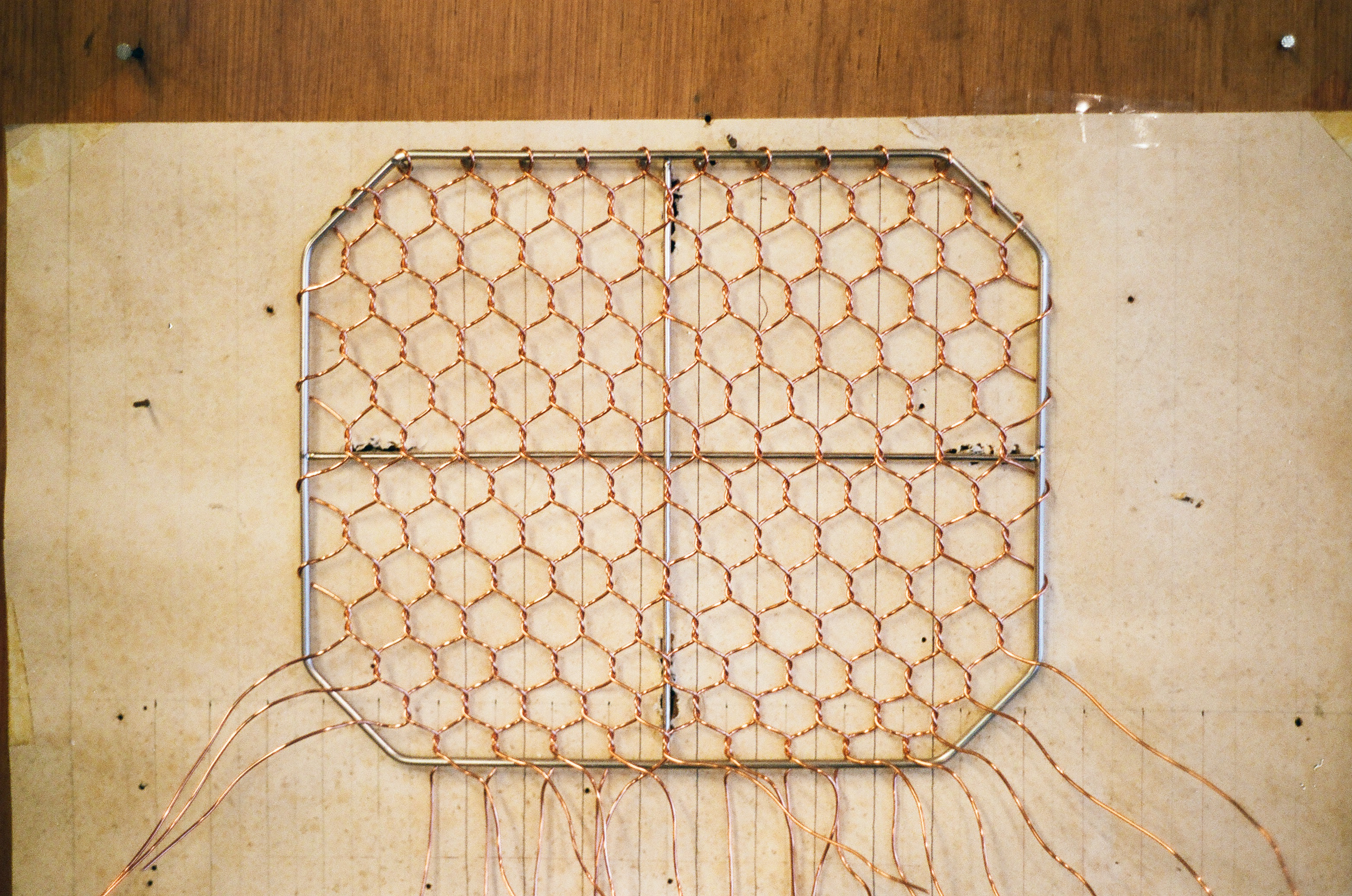

「手で編む、金網」

辻和金網3 代目 辻泰宏さん(創業1933 年/ 京都市中京区)

金網も眼鏡も、機械によってつくられている工業製品の一つだと思われている。しかし、実際は金網も眼鏡も人が手でつくっているものもある。それは手でしか作れない何かがあるから。辻和金網の金網も手で編まれている。辻和の金網について、3 代目の辻泰宏さんにお話を伺いました。

金網について

機械には真似できない

京都の金網の起源は平安時代にさかのぼると言われています。広く普及し始めたのは明治時代頃から。一時は京都にも60 軒ほど金網屋があったようです。しかし、プラスチック製品が出てきたり、機械化が進んだりという時代の波で、今では4 軒ほどになってしまいました。 でも、そんな中だからこそ、手作りならではの、工夫を凝らした細工が発達したのかもしれないね。

なぜ手編みにこだわっているかというと、お客さんの要望に応えられるから。機械製造だと「このサイズのものを一つだけ作って」というのは難しい。うちの人気商品である焼き網なんかもお客さんのリクエストから生まれた物です。「持ち手がついてたら楽や」とか「網が上に開いたら洗いやすい」とか、いろんな声が集まって今の形になりました。やっぱりお客さんの声ってすごいね。

なぜ手編みにこだわっているかというと、お客さんの要望に応えられるから。機械製造だと「このサイズのものを一つだけ作って」というのは難しい。うちの人気商品である焼き網なんかもお客さんのリクエストから生まれた物です。「持ち手がついてたら楽や」とか「網が上に開いたら洗いやすい」とか、いろんな声が集まって今の形になりました。やっぱりお客さんの声ってすごいね。

京都だからこそ残った、手編みの金網

うちでは茶こしや豆腐すくい、焼き網など、料理に使う金網を主に作っています。 僕のおじいちゃんが初代で、昭和9 年が創業なんですけど、当時は一般向けの商品は作っていなかった。ずっと料理屋さんやお菓子屋さん向けの商品を作っていました。京都で金網が残ってこれたのは、やっぱり料亭や菓子屋が多かったからだと思うね。

伝統とは

時代の変化についていく

伝統にあんまりこだわりすぎないことは大事かな。やっぱり残していかなあかん物は残していかなあかんし、でもそれにばっかりこだわっていたら、時代についていけなくなる。やっぱり時代も移り変わっていってるのでね。そういう風に商品も作っていかないと。うちの商品は台所関係の物が多いので、台所の変化にも対応していかないといけないんです。昔は台所って掛けるところが多かったんやけど、最近のキッチンは掛けるところが少ないでしょう。そういうところに気を配ってものづくりをしています。

継承について

あまり教えすぎない

例えば一つの技術を教えてもらっても、微妙に人それぞれやり方が違うんです。網目を見たら誰が編んだか分かる。技術もいかに自分のものにするか、自分なりにコツをつかむかどうかが大事かなと思います。表面的なやり方は最初教えるけど、あまり教えすぎないようにしています。その方が早く覚えるんだよね。

譲れないこととは

まずは丈夫さ

物を作るときに大切にしているのは、まずは丈夫さを考えて、その次に使い勝手の良さ、最後に見た目、かな。やっぱり長いこと使ってくれてるってお客さんが言ってくれる時、うれしいね。その辺を常に思って作ってます。